Rexroth Servo Valve 4WS2EM

Description

Reviews

Download:

Data Sheet of 4WS2EM 10 Series

Data Sheet of 4WS2EM 10 Series

REXROTH Type Code of 4WS2EM Series

REXROTH Type Code of 4WS2EM Series

Rexroth Servo Valve 4WS2EM Description

Heash provide Rexroth Servo Valve 4WS2EM and 4WSE2EM, new and original. Feel free inquiry us please if you interested in any type of 4WS2EM 6, 4WS2EM 10, 4WS2EM 16, 4WSE2EM 6, 4WSE2EM 10, 4WSE2EM 16, 4WSE2ED 16, 4WS2ED 16, 4WSE3E 16, 4WSE2E 25, 4WSE2E 32...

Rexroth 4WS2EM/4WSE2E Mare electrically operated, 2-stage directional servo valves. They are mainly used to control position, force, pressure or velocity.

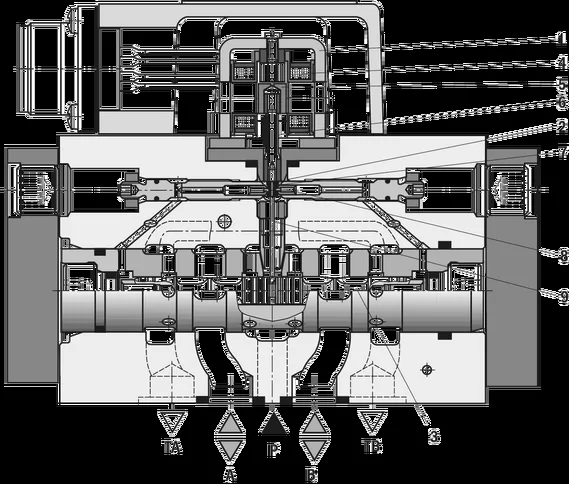

These valves are made of an electro-mechanical converter (torque motor) (1), a hydraulic amplifier (principle: nozzle flapper plate) (2) and a control spool (3) in a sleeve (2nd stage) which is connected with the torque motor via a mechanical feedback.

An electrical input signal at the coils (4) of the torque motor generates a force by means of a permanent magnet which acts on the armature (5), and in connection with a torque tube (6) results in a torque. This causes the flapper plate (7) which is connected to the torque tube (6) via a bolt to move from the central position between the two control nozzles (8), and a pressure differential is created across the front sides of the control spool (3). The pressure differential results in the control spool changing its position, which results in the pressure port being connected to one actuator port and, simultaneously, the other actuator port being connected to the return flow port. The control spool is connected to the flapper plate or the torque motor by means of a bending spring (mechanical feedback) (9). The position of the control spool is changed until the feedback torque across the bending spring and the electro-magnetic torque of the torque motor are balanced and the pressure differential at the nozzle flapper plate system becomes zero. The stroke of the control spool and consequently the flow of the servo valve are controlled proportional to the electrical input signal. It must be noted that the flow depends on the valve pressure drop.

External control electronics (servo amplifier) serve the actuation of the valve, amplifying an analog input signal (command value) so that with the output signal, the servo valve is actuated in a flow-controlled form.

Rexroth Type 4WS2EM 10...

Rexroth 4WS2EM Technical Data

|

Type |

4WS2EM...XN-114 |

||

|

Nenngröße |

10 |

||

|

Geräteserie |

|

5X |

|

|

Porting pattern |

|

ISO 4401-05-05-0-05 |

|

|

Einbaulage |

|

Any - if it is ensured that during start-up of the system, the valve is supplied with sufficient pressure (≥10 bar)! |

|

|

Surface protection |

Valve body, cover, filter screw |

|

nitro-carburated |

|

Cap |

|

anodized |

|

|

Storage temperature range |

°C |

-20 … +80 |

|

|

Masse |

kg |

3.56 |

|

|

Ambient temperature range |

°C |

-30 … +80 |

|

Heash provide Rexroth Servo Valve 4WS2EM and 4WSE2EM, new and original. Feel free inquiry us please if you interested in any type of 4WS2EM 6, 4WS2EM 10, 4WS2EM 16, 4WSE2EM 6, 4WSE2EM 10, 4WSE2EM 16, 4WSE2ED 16, 4WS2ED 16, 4WSE3E 16, 4WSE2E 25, 4WSE2E 32...

Rexroth 4WS2EM Features

Rexroth Directional servo valve for intended use in potentially explosive areas of zone 2 and 22

Valve to control position, force, pressure or velocity

2-stage servo valve with mechanical feedback

1st stage nozzle/flapper plate amplifier

For subplate mounting: Porting pattern according to ISO 4401-05-05-0-05 with ports X and Y; subplates available in FE/ZN version

Dry control motor, no contamination of the solenoid gaps by the hydraulic fluid

Can also be used as 3-way version

Wear-free control spool return element

External control electronics in Euro-card format or in modular design (separate order)

Valve is adjusted and tested

Internal or external pilot oil supply and pilot oil return available

Control spool with flow force compensation

Control sleeve centrically fixed, thus low susceptibility to temperature and pressure

Pressure chambers at the control sleeve with gap seal, no wear of seal ring

Filter for 1st stage freely accessible from the outside

| R900772317 | 4WS2EM10-5X/60B11T315K31CV-114 |

| R901016900 | 4WS2EM10-5X/60B0T315K31CV-112 |

| R900939884 | 4WS2EM10-45/75B3T315K8CV-94 |

| R901316772 | 4WS2EM10-4X=75B3T315K8CV-94 |

| R900733233 | 4WS2EM10-5X/60B0T210K31CV-112 |

| R901113388 | 4WS2EM10-5X/30B11ET315K8DV |

| R900909219 | 4WS2EM10-5X/75B11ET315K31EV |

| R901039313 | 4WS2EM10-5X/60B11T315K31CV |

| R900731499 | 4WS2EM10-5X/10B11ET315K31DV |

| R900750594 | 4WS2EM10-51/10B11ET315K8DV |

| R900936559 | 4WS2EM10-4X/75B2ET315K8EV |

| R900940047 | 4WS2EM16-2X/150B12T315K8CV-114 |

| R901095313 | 4WS2EM10-5X/20B11T315K31EV |

| R901006867 | 4WS2EM105X/45B11ET210K8AV |

| R900421035 | 4WS2EM10-4X/75B2ET315K8DM |

| R900385127 | 4WS2EM10-4X/60B2ET315K8DM |

| R900944630 | 4WS2EM16-2X/200B12T315K8CV-114 |

| R901007772 | 4WS2EM6-21/20B11XNET315K17EV-100 |

| R901007768 | 4WS2EM6-2X/20B11XNET315K17EV-102 |

| R901009654 | 4WS2EM6-2X/5B11XNET315K17EV-102 |

| R901217098 | 4WS2EM6-2X/5B11ET315K17EV-116 |

| R900733235 | 4WS2EM10-5X/90B0T210K31CV-112 |

| R900384103 | 4WS2EM10-4X/60B2ET315Z8DM |

| R900711077 | 4WS2EM10-5X/90B11T315K31CV-114 |