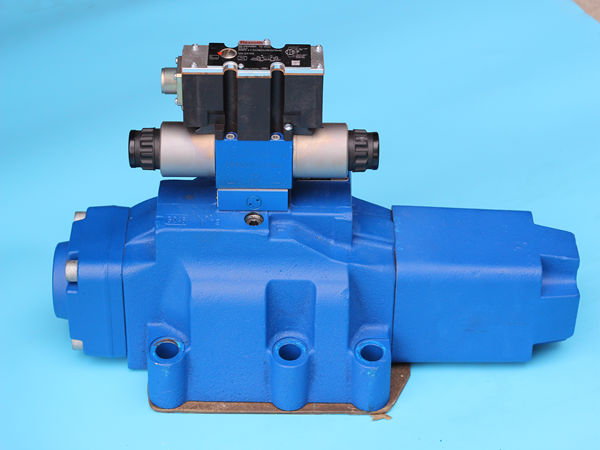

Rexroth Proportional Directional Valve 4WRZE

Description

Reviews

Download:

Rexroth Proportional Directional Valve 4WRZE Description

Rexroth 4WRZE hydraulic proportional directional valve is a high-performance control valve, with a pilot design and proportional solenoid operation ensuring fast response and high-precision control. The stability and wide applicability of the product make Rexroth 4WRZE valve widely used in various industrial and mechanical hydraulic equipment, meeting the demand for precise hydraulic control in industrial automation and mechanical equipment.

In terms of usage, Rexroth 4WRZE series proportional valves are widely used in various industrial fields that require high-precision and high response control due to their excellent performance, such as, Machine tool industry: Used for feed systems of CNC machine tools, machining centers, and other equipment to achieve high-precision position control; Plastic machinery: Used as a hydraulic system for equipment such as plastic injection molding machines and extruders, achieving precise control of pressure and flow; Metallurgical industry: Hydraulic systems used in metallurgical equipment, such as blast furnaces, continuous casting machines, etc., achieve high-precision and high response control.

The above are only some typical application fields. In fact, Bosch Rexroth 4WRZE servo valves have a very wide range of applications, covering almost all fields that require high-precision hydraulic control. Hydraulic systems applicable to the following industries or equipment: metallurgy, oil fields, power plants, cement plants, mining machinery, steel plants, ships, engineering machinery, petrochemical, maritime engineering, paper mills, wood processing machinery, rubber processing and manufacturing, grate coolers, thin oil stations, vertical mill hydraulic systems, rollers, bulldozers, cranes, loaders, concrete pump trucks, excavators, machine tools, injection molding machines, blow molding machines, presses, drilling machines.

Rexroth valve 4WRZE Features

Bosch Rexroth 4WRZE valve model type as like: R900954657 4WRZE16E100-7X/6EG24ETK31/A1D3M, R901010338 4WRZE 25 W6-325-7X/6EG24N9K31/F1M, R900967570 4WRZE 25 R3-325-70/6EG24N9ETK31/A1D3M, R901017042 4WRZE 10 W8-50-7X/6EG24N9TK31/A1D3M, R901506455 4WRZE16E1180-7X/6EG24N9ETK31/A1D3M, R901426377 4WRZE16 W6-180-7X/6EG24N9ETK31/A1D3M, R901420797 4WRZE16E180-7X/6EG24N9ETK31/A1D3M, R900974755 4WRZE 16 W8-150-7X/6EG24EK31/A1M, R900744846 4WRZE16W6-100-7X/6EG24N9K31/F1D3M, R900706613 4WRZE25W8-325-7X/6EG24EK31/A1D3M, R900702101 4WRZE32E360-7X/6EG24N9K31/A1D3M, R901155720 4WRZEM25E220-1X/6EG24K31/A1D3M, R900947696 4WRZE10E1-85-7X/6EG24N9ETK31/A1D3V, R900954669 4WRZE25E1-325-7X/6EG24ETK31/A1D3M, R901062222 4WRZE16E1-150-7X/6EG24N9EK31/F1D3M, R900753993 4WRZE25-W8-325-7X/6EG24N9EK31/F1D3M, R901137084 4WRZE32E520-7X/6EG24N9K31/F1D3M, R900975860 4WRZE25EB220-7X/6EG24K31/A1M, R901145343 4WRZE16 W8-150-7X/6EG24N9ETK31/F1M, R901070268 4WRZE25W8-220-7X/6EG24N9K31/A1D3M, R900769053 4WRZE32W8-520-7X/6EG24N9K31/A1D3M, R901067668 4WRZE10W6-50-7X/6EG24N9K31/F1M, R900954642 4WRZE 16 W6-150-7X/6EG24N9ETK31/F1V, R900785482 4WRZE 25 W9-325-72/6EG24N9ETK31/F1D3M, R900932993 4WRZE 10 W6-85-7X/6EG24N9ETK31/A1D3V, R900700446 4WRZE25R325-7X/6EG24N9K31/A1D3M, R901072852 4WRZE16W8-150-7X/6EG24N9TK31/F1D3M, R900724781 4WRZE10W8-85-7X/6EG24N9ETK31/F1D3M, R900964255 4WRZE32W8-520-7X/6EG24N9K31/A1D3V, R901183003 4WRZE 32 W8-520-7X/6EG24K31/A1D3M, R900949807 4WRZE25W8-325-7X/6EG24N9ETK31/F1D3V, R901050603 4WRZE25E325-7X/6EG24K31/A1M, R900751835 4WRZE10W6-50-7X/6EG24N9EK31/A1D3M, R900759703 4WRZE 16 W8-100-7X/6EG24N9EK31/A1D3M, R900949751 4WRZE16W8-150-7X/6EG24N9EK31/F1D3V, R901110196 4WRZE16W6A150-7X/6EG24N9ETK31/A1D3M, R901054349 4WRZE10W8-85-7X/6EG24N9TK31/F1D3M, R900948482 4WRZE25W8-220-7X/6EG24N9K31/A1D3V, R901062036 4WRZE 32 W6-520-7X/6EG24N9EK31/A1D3M, R901072891 4WRZE25W6-325-7X/6EG24N9K31/F1D3M, R901014940 4WRZE25W8-325-7X/6EG24N9K31/F1D3M, R901055378 4WRZE32W8-520-7X/6EG24N9K31/F1D3M, R901171185 4WRZE16W6-100-7X/6EG24N9K31/A1D3M, R900970169 4WRZE16W8-100-7X/6EG24N9K31/F1D3V, R900706549 4WRZE16 W8-150-7X/6EG24N9ETK31/F1V, R901126301 4WRZE52W8-1000-7XF/6EG24N9K31/F1V, R901136400 4WRZE 52 W8-1000-7XF/6EG24K31/A1M, R901230379 4WRZE 52 W8-1000-7XF/6EG24K31/A1D3M, R901266844 4WRZE 52 W8-1000-7XF/6EG24N9K31/F1D3V, R901274313 4WRZE 52 W6-1000-7XF/6EG24K31/A1D3M, R901359337 4WRZE52E1-1000-7XF/6EG24N9K31/F1D3M, R901428340 4WRZE52E3-1000-7XF/6EG24N9K31/A1M, R901527040 4WRZE52E1-1000-7XF/6EG24N9K31/A1D3M.

HEASH TECHNIQUE B.V., is pleased to be your components source for hydraulics and electronics from Europe. Welcome enquiry us if you demand Rexroth valve 4WRZE or any other Rexroth valves, pumps, motors, as: Rexroth Prop./Servo Valves: 4WRAE, 4WRZE, 4WREE, 4WRPEH, 4WRKE, 4WRDE, 4WRTE, DBEME, 4WS2EM, 4WSE3E, 4WRSEH, 3DREME, 3DREPE, VT-DFPE, M-3SED, M-3SEW, STW, 2WFCE, 2WRCE, SCA, ZDC, DBW, DBWA, DBA, 3FRE, 2FRW, 4WRH, 3DRG, LC2A, Z4WEH, 4WRLE,... Rexroth Pump/Motor: A4VSO, A11VLO, SYDFEE, P A4VSG, A4CSG, A7VO, A7VK, A17FO, A4VG, PV7, A15VO, A6VM, A10VSO, A20VO, A2FM, A2FO, A4FM, A4FO,... Hengst filter/element=Rexroth filter/element MNR as R928...